Make Sure You Are Educated

At Mid-Michigan Metal Sales we want to make sure your next roof will be the last roof you will ever need. With a little bit of education, you can make sure you choose the correct steel for your new roofing project. Choosing the correct steel is one of the biggest factors in making sure your roof lasts for several decades.

At Mid-Michigan Metal Sales all of our Hardy Brand panels and trim are made from AZ-50 Galvalume® Steel (equivalent to G90 galvanized) or AZ-55 Galvalume® Steel depending on which type of panel is purchased.

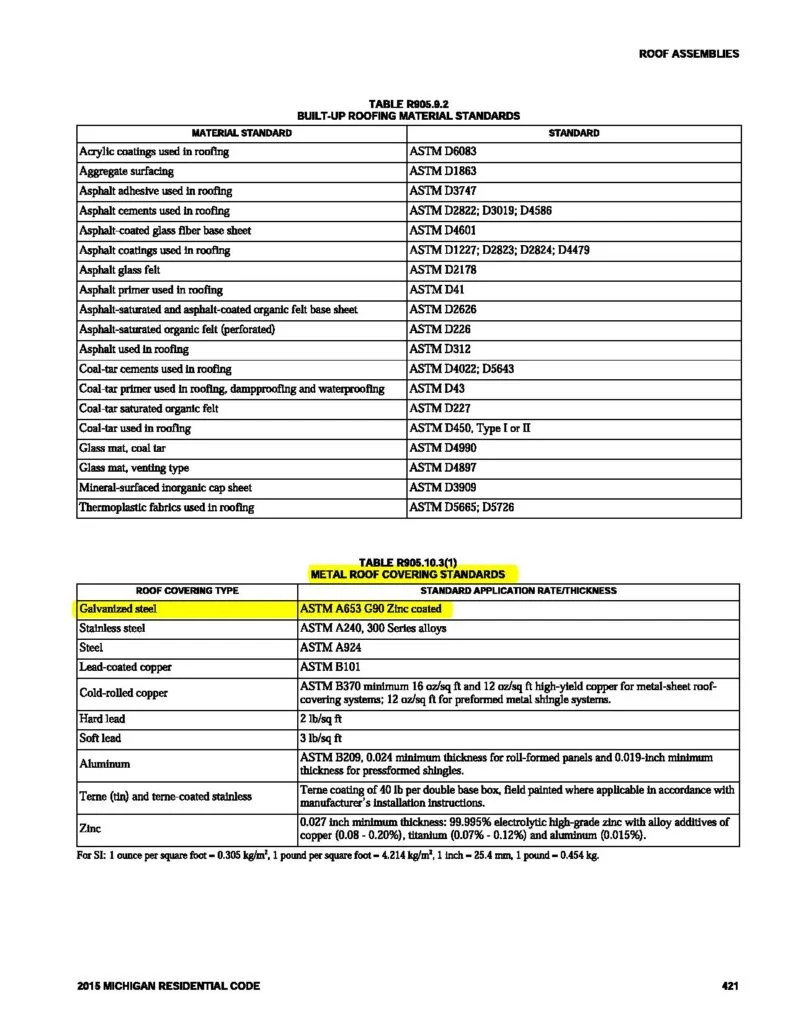

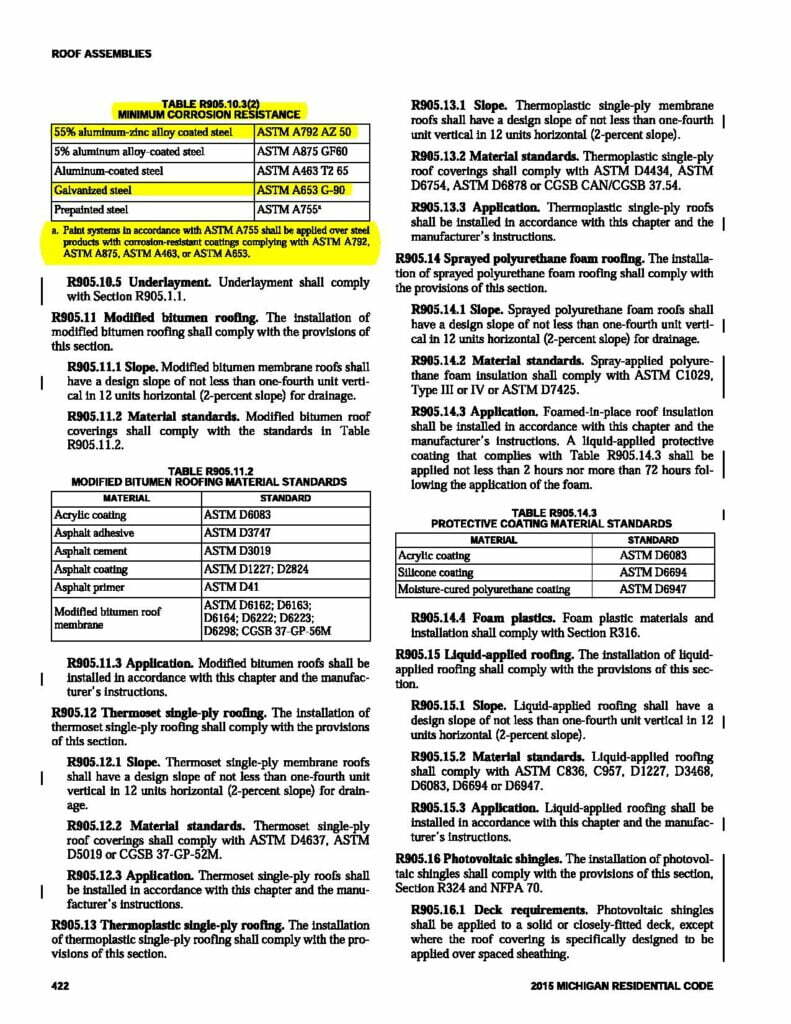

In the State of Michigan, residential building code requires that steel roofs are made from a minimum of an AZ-50 Galvalume® or G90 Galvanized Steel.

To view pages 421 & 422 regarding the minimum quality of steel allowed to be used as a roof covering from the 2015 Michigan Residential Code book Click Here. (pdf.) or click on the images below.

When shopping for your new steel roof you need to make sure you are being quoted for at least an AZ-50 Galvlaume® or G90 Galvanized panel. If you are receiving a quote from one of our competitors, be sure you are not being quoted for a G60 Galvanized Steel panel and being told you can use it for a steel roof. We have been informed that many lumber yards and big box retailers tell customers that they can use it as roofing which is incorrect. According to the current Michigan Residential Building Code book, you will not be able to legally install a G60 galvanized steel panel on a residential roof in the State of Michigan. (See above pictures)

The information below is from the Metal Roofing Alliance. Visit their web site here to learn more about steel roofing in general.

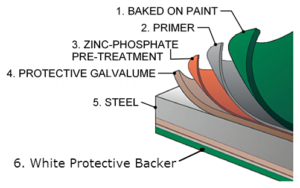

Steel roofing for residential applications is very lightweight with the heaviest product weighing about 1.5 pounds per square foot when installed. The products are initially produced in giant rolls at the steel mills. They are then coated with a metallic coating to prevent rust at the steel plant. The rolls are then painted at a coil coating plant using high-speed paint lines that bake on the coating. The painted coil is then shipped to a roofing manufacturer where it is formed into long panels by a process called rollforming or they are stamped into individual shingles using large presses.

Metallic Coatings

All steel roofing has a protective barrier on both sides of the sheet called a metallic coating which protects against rusting. This is underneath and separate from any paint which imparts color to the product. There are two types of metallic coatings used:

Galvanized: This is 100% zinc in various thicknesses depending upon the product usage.

Galvalume: A mixture of aluminum and zinc. (55 percent by volume aluminum)

Metallic coatings “sacrifice” themselves to protect the iron (Fe) in steel from oxidation when exposed to the air and moisture is present. Zinc is a more “active” metal than iron so it oxidizes first and forms a protective barrier — zinc oxide, before the iron (Fe) in the steel can become Ferric Oxide (rust). When zinc is combined with aluminum to form Galvalume there is even more protection in most circumstances.

Different Levels of Protection

There are differing amounts of metallic coating used on sheet steel depending upon its final product application. For agricultural applications, galvanizing levels called G-40 or G-60 may be used quite successfully. For houses, the MRA recommends a minimum of G-90 be used. This is in accordance with the Guidelines for Residential Metal Roofing published by the Metal Construction Association. The greater the number, the longer the protection against rust will last.

The numbers G-40; G-60; and G-90 refer to the ounces of zinc per 100 square feet of sheet steel coated (top and bottom). G-90 will have 90 ounces of Zinc- 45 ounces on each side per 100 square feet of roofing sheet steel.

Galvalume has a designation AZ-50 or AZ-55. These are equivalent levels to G-90 galvanized product. However, in many years of exposure testing Galvalume has proven to be up to three times more effective in preventing rust from appearing on the sheet steel.

We want to make sure you make an educated decision on your next roofing project and hopefully the information on this page has helped you distinguish the types of steel available in the market and explain that not all steel is created equal. Be sure to check out the Metal Roofing Alliance’s web site to learn even more about steel roofing. Visit metalroofing.com to learn more.

To view additional FAQ’s on steel roofing follow the link here.